LDX-026A Customized large TCT saw blade sharpening machines

manufacturer

Carbide saw blade processing needs to be considered:

1,First of all, for the material of the saw blade, 65Mn spring

steel has excellent elasticity and plasticity, and its heat

treatment hardenability is not very good. Therefore, we can use it

to cut areas with low requirements, mainly when the heating

temperature is low and it is very easy to deform.

2,When the carbide saw blade is processed, it is also necessary to

consider its diameter, the number of serrated teeth, the thickness,

and the style of the tooth shape. These are also the parameters

that we need to apply in practical applications when we process the

saw blade.

3,The good or bad and normal use of the saw blade is very

beneficial to the improvement of the related quality of the product

and the shortening of the production period. Not only that, but

also can reduce a lot of processing costs for enterprises.

| Technical parameters: |

| Processing saw blade diameter range: ¢300- ¢ 1800mm |

| Saw blade aperture: ¢ 10-220mm |

| Saw blade thickness (steel plate): 1-12mm |

| Tooth pitch: 7-120mm |

| Tooth surface angle: 5 degrees to+30 degrees |

| Tooth top back angle: 6-45 degrees |

| Left and right inclination of teeth: tooth tip/tooth surface 45

degrees |

| Blade grinding stroke range: maximum 25mm (adjustable) teeth/minute |

| Grinding speed: 0.5-6mm/s |

| Working speed: maximum 20 teeth/minute |

| Grinding wheel size (outer diameter x hole): (¢ 125mm x ¢32mmX1mm) |

| Negative chamfer grinding: -27 degrees |

| Grinding head rotatable angle: 90 degrees and 180 degrees |

| Grinding wheel linear speed: 26m/s |

| Flow rate of coolant water pump: 501/min |

| Volume of coolant cylinder: 85L |

| Total power: 2.2 kW |

| Voltage: three-phase 380v |

| Mechanical weight: 1200KG |

| Mechanical dimensions (length x width x height): 1800X1400X1800mm |

| Technical features: |

| The design of this machine refers to the characteristics of similar

domestic and foreign models, absorbs and analyzes the advantages of

the same type, and makes some functional improvements. This

equipment is specifically designed for grinding large alloy saw

blades. |

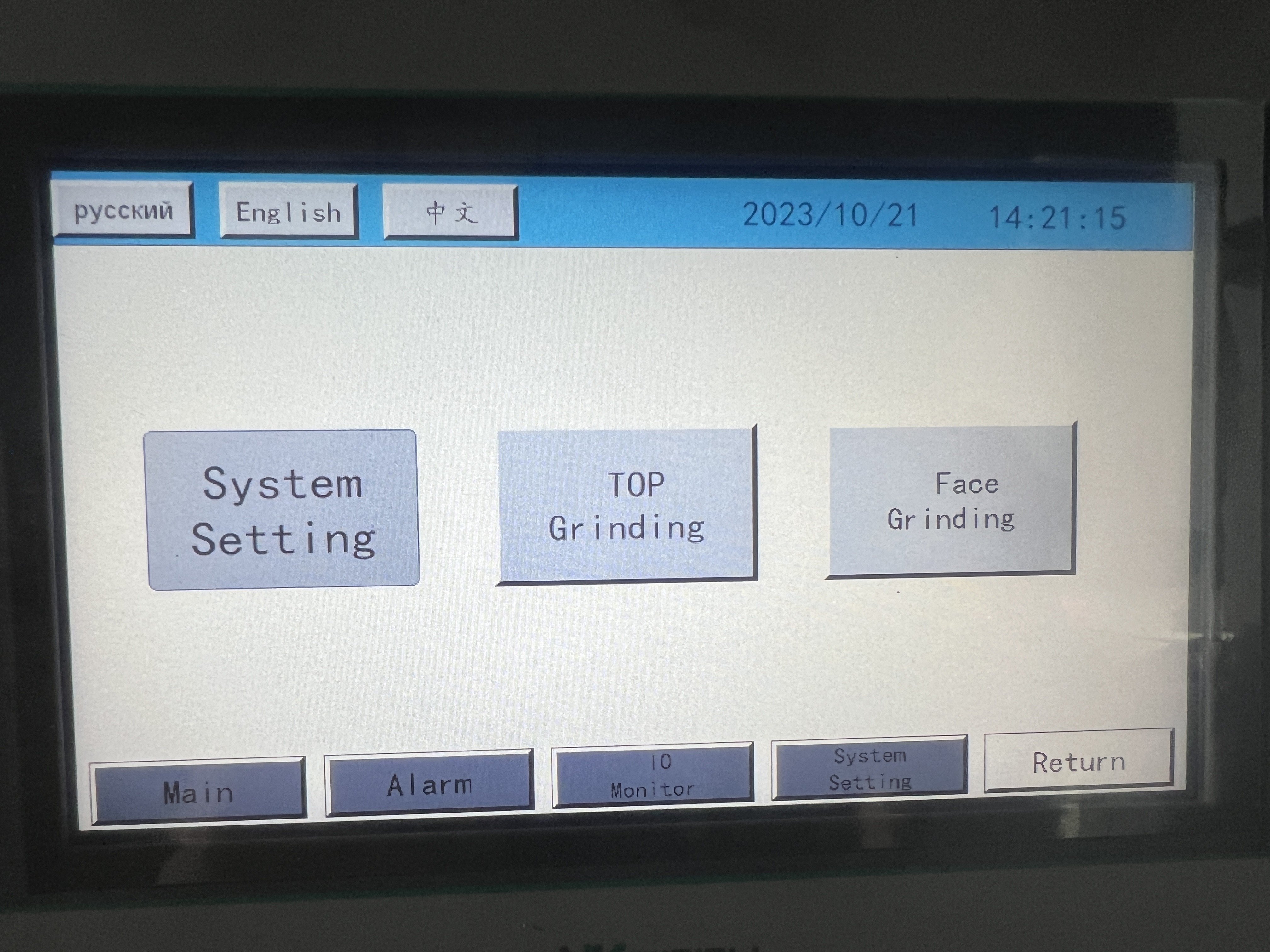

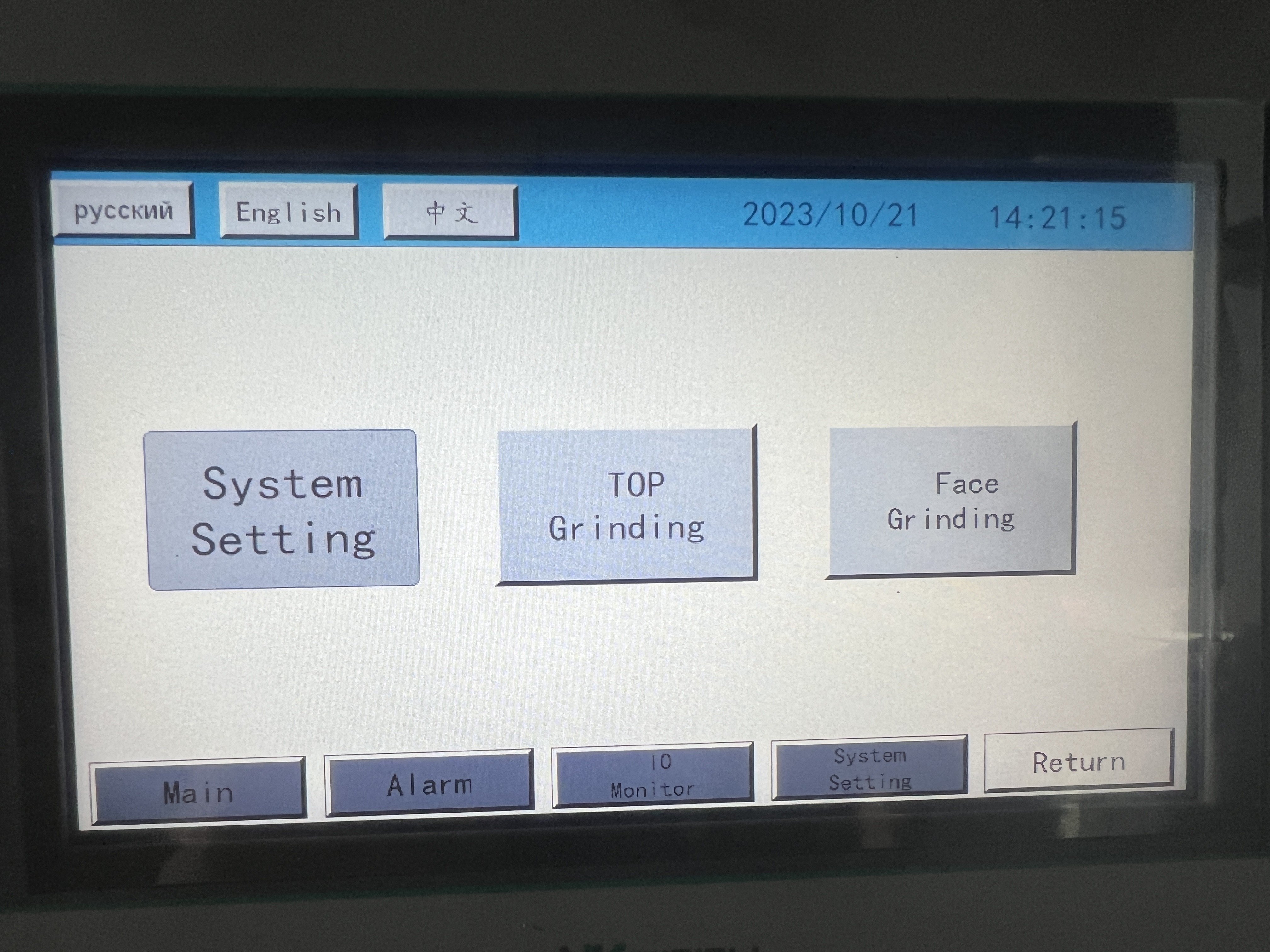

| 1. Pre set multiple sets of tooth profiles for one click

multifunctional operation. |

2. The flat teeth of the ladder can be completed in one go, with

CNC grinding and any tooth shape, which can increase efficiency by

three times; Improved gear extraction operation to improve accuracy

and extend service life.

|