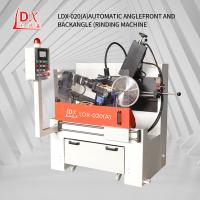

LDX-020A Automatic woodworking saw blade front and rear Angle

grinding machine

What do we need to pay attention to when grinding and reprocessing

the band saw blade gear grinding machine?

1,When grinding again, the Original angle of the new state of the

saw blade should be kept for grinding, otherwise it will cause loss

due to poor grinding.

2,The coated teeth on the tool head are different from the usual

circular saw blades, and the grinding method is different, please

pay special attention to it.

3,After grinding, please confirm whether the tool head is still

off, defective, unground, which will cause poor cutting or injury.

4,Saw blade reprocessing (reaming) is recommended not to exceed the

original hole 20mm, otherwise it will cause detensioning and the

cutting effect of the saw blade will be affected.

5,As we all know, high-speed processing technology is developing

rapidly, and to promote this development trend is CNC grinding

machine, how to make reasonable use of the performance of CNC

machine tools (attributes: automatic machine tools) and maintain

the accuracy of the machine tools (degree), it is crucial, below,

let's talk about some details and common sense machine tools need

to pay attention to in the power supply, I hope it was helpful.

Can high speed circular saw be repaired?

1,Before repairing the high-speed circular saw machine, it is first

necessary to troubleshoot the fault and find out the specific

damage or cause of the fault. Usually, the common faults of

high-speed circular saw machines include motor damage, blade

damage, transmission device failure, etc. Through careful

observation and detection, the specific fault location can be

identified and the problem can be solved in a targeted way during

the repair process.

2,If the motor of the high-speed circular saw machine fails, it

needs to be repaired or replaced in time. Motor failures may

include burnt-out windings, broken cables, damaged bearings, etc.

When repairing the motor, it is necessary to repair or replace the

fault part according to the specific situation, and ensure that the

motor can operate normally. In addition, regular maintenance and

maintenance of the motor is also an important measure to prevent

failure.

3,The blade of the high-speed circular saw machine is its main

working part, and it needs to be sharp and stable when working. If

the blade is worn or damaged, it needs to be replaced in time to

ensure work efficiency and quality. When replacing a blade, select

one that meets specifications and requirements, and ensure that it

is properly and securely installed. In addition, regular grinding

and inspection of the blade is also an effective way to extend the

service life of the blade.

4,The transmission system of high-speed circular saw machine

includes the main transmission belt, bearings, gears and other

components, if the failure will cause the machine to not work

normally. When overhauling the transmission system, it is necessary

to carefully check whether the various parts are loose, worn or

damaged, and repair or replace the faulty parts in time. Keeping

the transmission system in good condition can ensure the stable

operation and working efficiency of the high-speed circular saw

machine.

5,In the repair of high-speed circular saw machine, it is necessary

to strictly abide by the safe operation procedures to ensure the

safety of maintenance personnel and the machine. When disassembling

or assembling the machine, it is necessary to cut off the power

supply and ensure that the machine stops running to avoid

accidental injury. It is necessary to have a full understanding of

the various components and operation methods of the high-speed

circular saw machine to ensure the safety and reliability of the

maintenance process.

| Technical parameter: |

| Processing saw blade diameter range: ¢100- ¢800mm |

| Saw blade aperture: ¢ 10-220mm |

| Saw blade thickness (steel plate): 1-12mm |

| Tooth pitch: 7-100mm |

| Tooth surface angle: 5 degrees to+20 degrees |

| Tooth top back angle: 1-20 degrees |

| Left and right inclination of teeth: tooth tip/tooth surface 20

degrees |

| Blade grinding stroke range: maximum 25mm (adjustable) teeth/minute |

| Grinding speed: 0.5-6mm/s |

| Working speed: maximum 20 teeth/minute |

| Grinding wheel size (outer diameter x hole): (¢ 125mm x ¢ 32mmX1mm) |

| Negative chamfer grinding: -15 degrees |

| Grinding wheel linear speed: 26m/s |

| Flow rate of coolant water pump: 501/min |

| Volume of coolant cylinder: 85L |

| Total power: 1.85 kW |

| Voltage: three-phase 380v |

| Mechanical weight: 700KG |

| Mechanical dimensions (length x width x height): 1500X1100X1700mm |

| Technical features: |

1. This equipment can grind aluminum TCT cutting alloy saw blades

and woodworking saw blades. It is easy to operate and can fully

extend the service life of TCT saw blades. Each blade can be reused

15-30 times. This equipment has received praise from many buyers.

|